Types of Stainless Steel Scrap

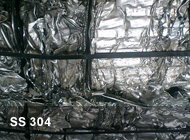

- SS 304

- SS 316

- SS 304

- Steel Pipes

Our Zinc Scrap include – Score and Dross. Zinc score consists of clean, dry and unalloyed zinc sheet scrap. Zinc Score is being used for production of zinc sheets also meant for printing industry, for common castable alloys and lead copper-zinc alloys; for hot zinc plating of ready-made products as well as materials; for producing zinc powder used in metallurgical industry and also for production of zinc oxide used in chemico-pharmaceutical industry; for fine chemicals; for acquiring zinc powder used in accumulators.

We offer Zinc Scraps in various forms like Die Cast, Zinc plates, Roofing Zinc, Irony Zinc Boring and Turning, Ingots etc and Selling Zinc Scrap in very reasonable price interested buyers may contact us.

Do You Know ?

In the late 1890s, German chemist Hans Goldschmidt developed an aluminothermic (thermite) process for producing carbon-free chromium. Between 1904 and 1911, several researchers, particularly Leon Guillet of France, prepared alloys that would be considered stainless steel today.

Types of Stainless Steel Scrap

Benefits of Stainless Steel Recycling:

Environmental concerns are a big part of today’s economy. Recycling is an accessible way for businesses and industries to reduce their carbon footprint and contribute to helping the environment. However, using recyclable materials isn’t just eco-friendly — it’s cost-effective.

According to research published in 2006 from the British Stainless Steel Association, recycling accounted for savings of nearly 33% of the energy used in current austenitic stainless-steel production worldwide. In a perfect scenario — in which all stainless came from 100% recycled stainless — global energy consumption used in stainless steel production would drop a further 51%. Since recycling stainless steel does not cause degradation, the amount of recycled content in stainless is often a matter of scrap availability. More scrap availability means less pollution, reduced energy requirements, and lower costs — for both producers and buyers of stainless steel.

It’s a win-win for all.

Stainless Steel Recycling Cost:

The prices recycling centres pay for scrap will depend on the market price for stainless steel. A range of factors influence pricing, including the current economy, industrial demand, scrap condition, and the stainless steel alloy in question. However, stainless steel scrap — even of lower-end alloys — is always in demand. So it’s often worth your time and effort to recycle any stainless steel scrap your business might produce. Demand stays high because recycled stainless scrap comprises up to 60% of new stainless steel. In fact, you can make “new stainless” from 100% recycled scrap. But there is rarely enough scrap to use because stainless steel is so durable. Since stainless takes so long to reach the end of its useful life, it may take decades for scrap to find its way to a recycling centre. This means that whether you’re collecting scrap from manufacturing and fabrication, cleaning up a demolition site, or looking to dispose of old or outdated equipment, stainless steel is worth recycling — both from an ecological and financial standpoint.